Ref. No. [UMCES] CBL 2013-020

ACT VS12-03

RESULTS of WAVE TANK TEST

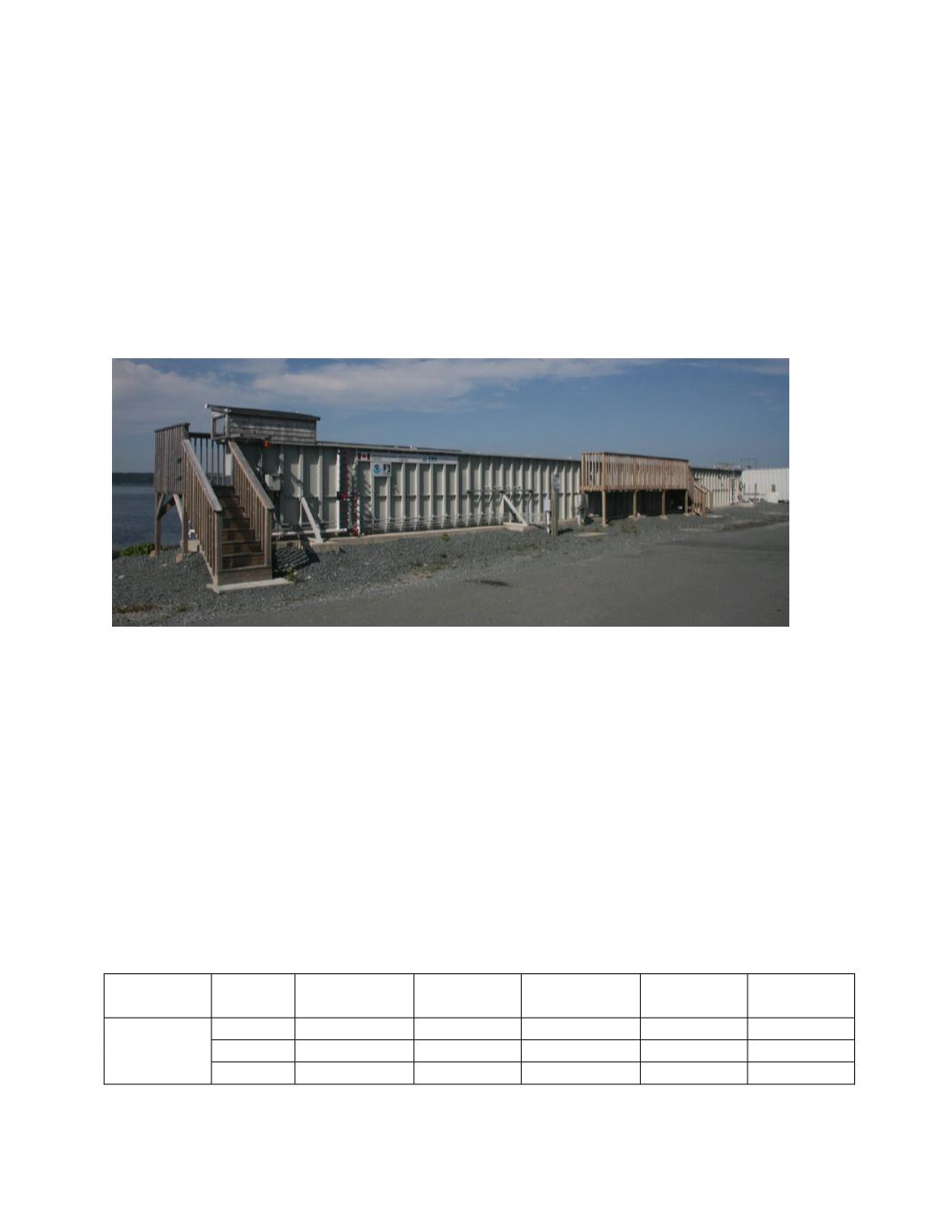

Tests were conducted at the Bedford Institute of Oceanography’s (BIO) Center for

Offshore Oil, Gas and Energy Research (COOGER) in their 32 m wave tank facility. This wave

tank was constructed at the BIO in collaboration between Fisheries and Oceans Canada (DFO)

and the U.S. Environmental Protection Agency (EPA) for controlled oil dispersion studies (Photo

3). The wave tank is able to continually produce breaking waves at precise locations in the tank

(Photo 4) and is fully equipped to enable measurements of dispersed oil in the water column. The

tank is equipped with a flap-type wave maker that generates waves with periods varying from

about 0.5 to 1.5 seconds. On the opposite end of the tank, a series of inclined screens is in place

to absorb wave energy and minimize reflection.

Photo 3.

Bedford Institute of Oceanography’s Wave Tank

Oil additions were performed by BIO research staff using established protocols. In brief,

oil was first added to two liters of the ambient bay water and mixed on a shaker plate for

approximately 15 minutes, with or without dispersant depending on the test. The oil slurry was

then poured slowly into the wave generating end of the tank (Photo 5 and 6) and allowed to be

mixed by wave motion. Oil concentrations become uniformly distributed throughout the tank

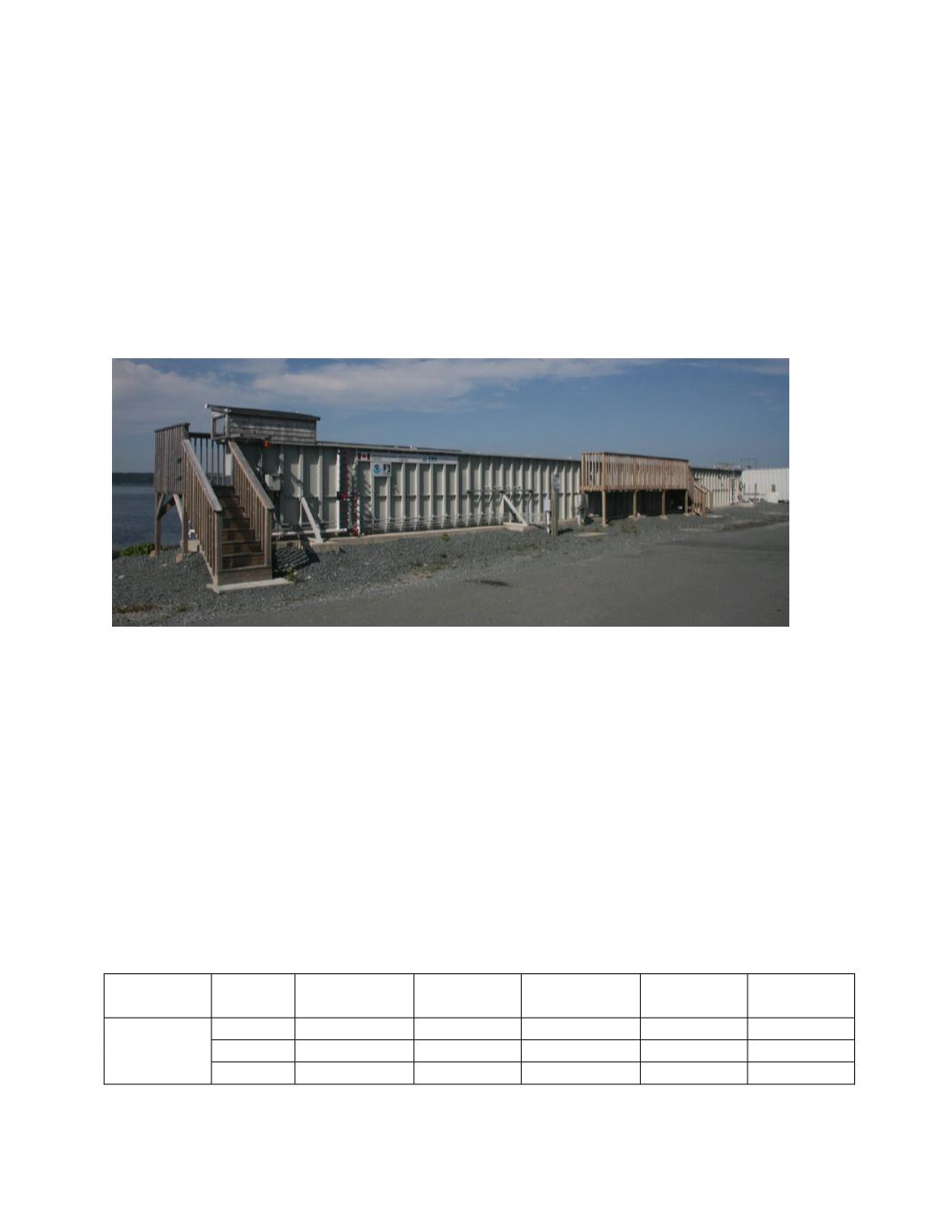

after approximately 30 minutes of mixing. A summary of the test conditions and background

water quality concentrations of the seawater used during oil additions are provided in Table 2.

Temperature and salinity conditions were consistent over the test period and chlorophyll and

CDOM levels were relatively low.

Table 2.

Comparison of ancillary physical and water quality conditions for hydrocarbon sensor

verification tests conducted in the wave test tank at the Bedford Institute of Oceanography, Halifax, Nova

Scotia.

Site

Temperature

(

o

C)

Salinity

Chlorophyll

(µg/L)

CDOM

A

400

, m

-1

Turbidity

(NTU)

BIO Wave

Tank

Min

8.3

14.5

0.1

0.61

0.3

Max

9.5

15.8

0.9

1.33

5.0

Mean

8.9

15.6

0.5

0.95

1.5

20