| The Nutrient Sensor Challenge moved into the lab testing phase over the course of a week in mid-July at the Alliance for Coastal Technologies Headquarters at the Chesapeake Biological Laboratory in Solomons, Maryland. Challenge participants had several days to prepare their instruments prior to lab testing. Representatives from five companies were on hand to test 8 sensors (4 nitrate sensors, 4 phosphate sensors). Sharing space, analytical equipment, and chemical reagents led to some really nice camaraderie among participants – even if ACT staff were quietly stressing if we had enough glassware and equipment on hand to keep everyone progressing smoothly. |

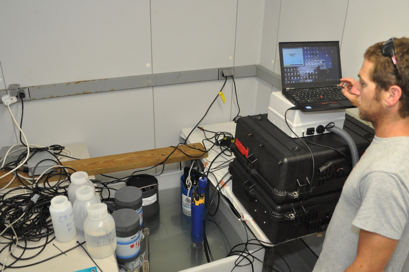

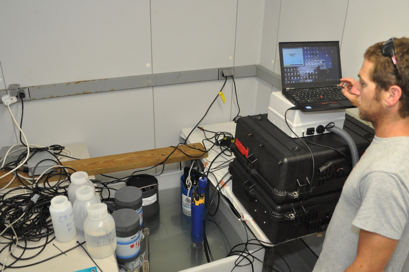

ACT technician Dave Loewensteiner getting the sensors ready for the lab test. |

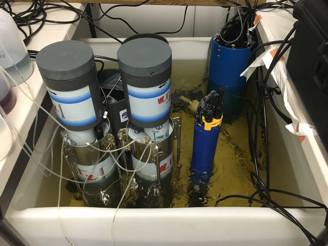

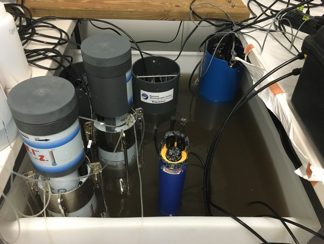

Each day during the week, instruments were all placed in a well-mixed 90 gallon testing tank and exposed to a different set of test conditions that were manipulated by ACT personnel (nutrient levels, temperature, salinity, turbidity, and organic matter). The purpose of altering these test conditions was to see how well the nutrient sensors performed under controlled conditions that approximate what the sensors could be faced with in a natural environment. Typically, each day instruments started at a zero or neutral condition, and over the course of the day increased changes to the test conditions occurred. By the end of the day, test conditions approximated the very highest levels that a nutrient sensor could be expected to encounter in the natural environment. ACT staff took water samples at regular intervals that were processed using standard laboratory techniques. Those samples were analyzed by the Nutrient Analytical Services Laboratory for nitrate and phosphate to serve as a reference dataset that will be used to quantify sensor performance. We conducted the tests in a controlled temperature room to ensure that temperature remained stable throughout the test. A new tank was brought in and swapped for the old one at the end of each day so that the sensors could acclimatize overnight back to neutral conditions. This was done to ensure that nothing about the previous day’s testing impacted subsequent testing. |

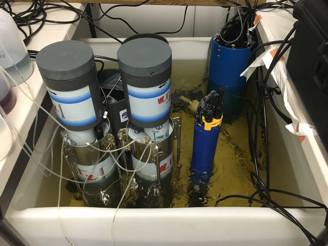

This tank is showing the zero or neutral conditions, which is how each test started. |

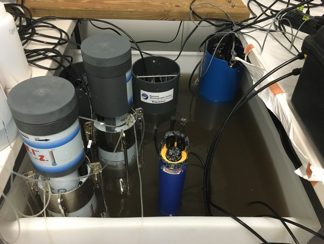

Shown here are the dissolved organic carbon (organic matter) test conditions. |

Shown here are the turbidity test conditions. |