Ref. No. [UMCES]CBL 2013-021

ACT VS12-05

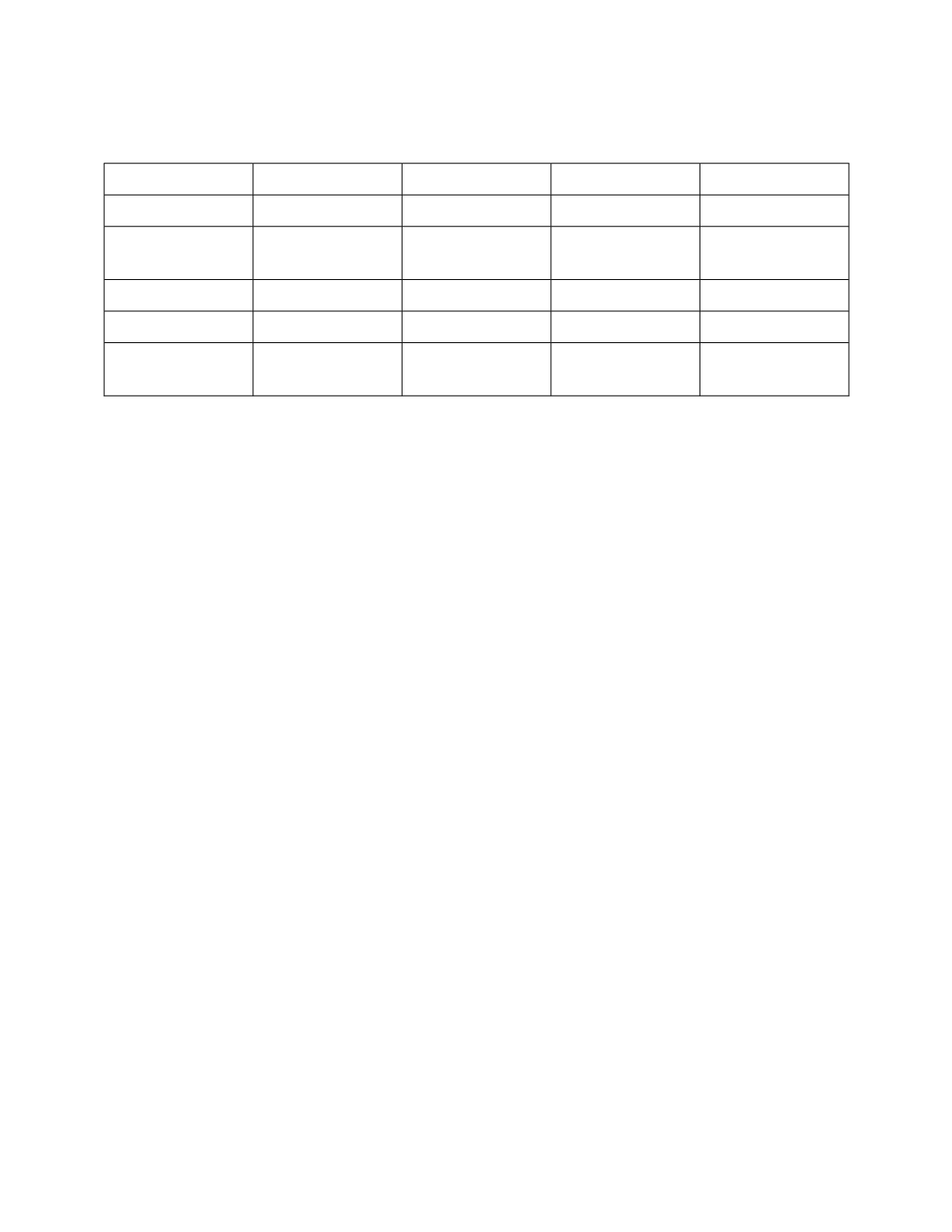

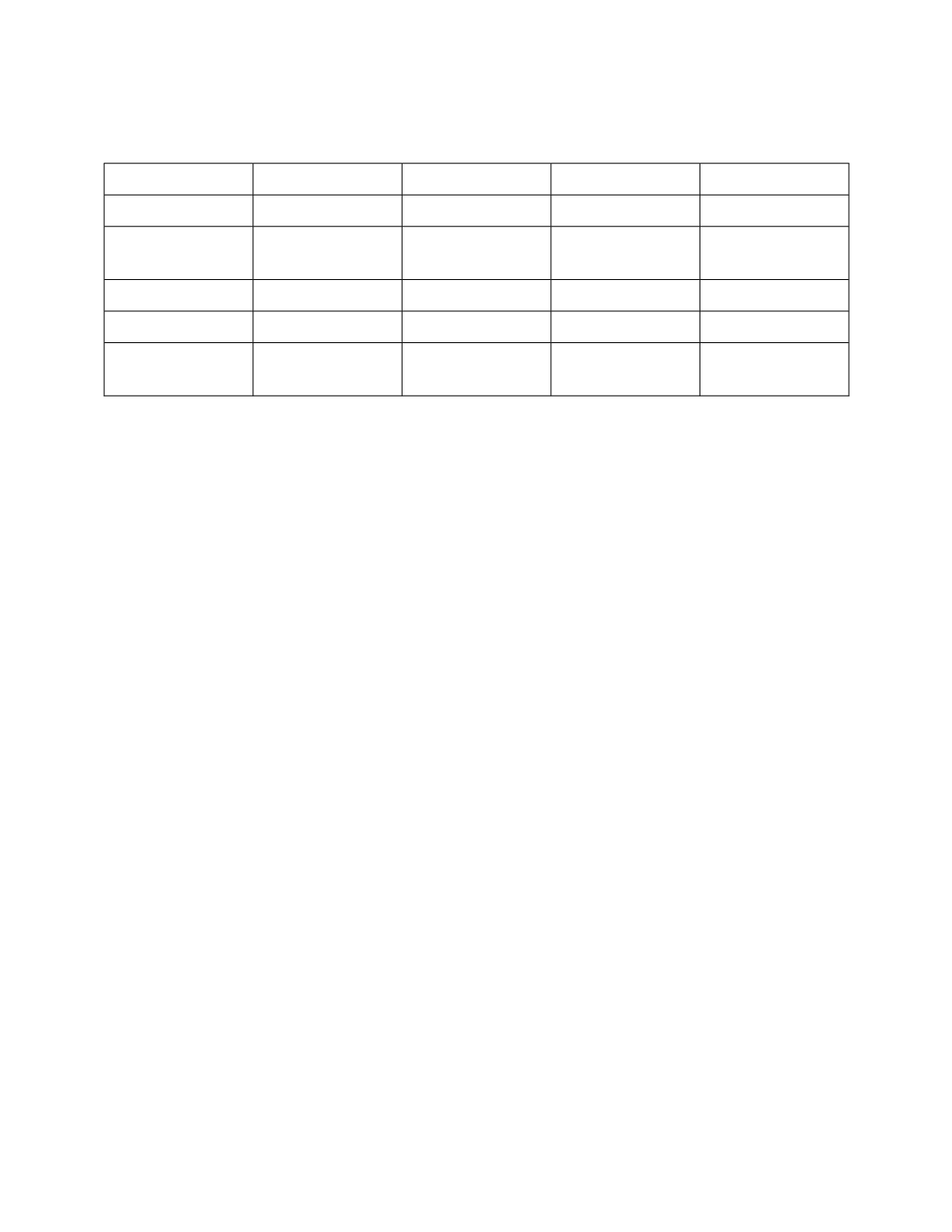

Table 1.

Challenge compounds for laboratory evaluations of hydrocarbon sensors.

Compound

Ex

Em

Carrier

Stock (ppm)

Carbazole

270

342, 358

methanol

5000

1,5-Naphthalene

Disulfonic Acid

270

380

0.05 M H

2

SO

4

5000

Quinine Sulfate

350

450

0.05 M H

2

SO

4

5000

Basic Blue 3

250, 320

430

water

5000

Diesel Fuel

SPEX CRM

250-300

350-500

methanol

5000

Performance against crude oils and dispersants in a Wave Tank Test

A test application of instrument response against crude oil compounds, with and without

addition of dispersant, was performed in a simulated water column using the DFO/US EPA

Wave Tank Facility located at the Bedford Institute of Oceanography, Dartmouth, Nova Scotia,

Canada. Reference samples were collected from the tank to allow real-time characterization of

the sample water with three-dimensional Excitation/Emission spectroscopy (EEMS).

Instrument performance was examined against two types of crude oil, Arabian Light

(weathered 7%) and Alaskan North Slope, run under two conditions including the pure oil

compounds and with compounds at oil to dispersant ratio of 25:1. The test materials were created

experimentally at the Bedford Institute of Oceanography (Department of Fisheries and Oceans,

Halifax, Nova Scotia) using the two source oils and Corexit 9500 dispersant. Experiments were

performed in a step-up addition batch mode with breaking waves to physically disperse the oil

throughout the tank. Oil additions were cumulative to the same batch of water and were made at

six timepoints at approximately one hour intervals. The amount of oil added ranged between 0 to

360 grams and produced oil concentrations of 0, 0.3, 0.6, 1.5, 3.0, 6.0, and 12.0 ppm,

respectively, at each consecutive step. Reference sampling occurred 50 minutes after each new

oil addition. Continuous instrument records were sub-sampled to the last 10 minutes of

equilibrated conditions of the exposure period and corresponding reference sampling times.

A Seabird SBE26+ CTD, SeaPoint chlorophyll fluorometer and LISST particle analyzer

were deployed to provide ancillary time-series data on water quality and to confirm degree of

physical dispersion of added oil. Reference samples were collected from three sampling inlet

ports distributed across the width of the tank and located adjacent to the sensor window. An

aggregate sample was produced for the reference sample analyses, except for hydrocarbon

subsamples which were taken and analyzed independently. Hydrocarbon analysis was conducted

on-site by certified COOGER BIO facility personnel using either gas chromatography with a

flame graphite detector (GCFID) or gas chromatography with a mass spectrometer (GCMS)

depending on concentration levels.